| NanoTwister | ||||||

|

| ||||||

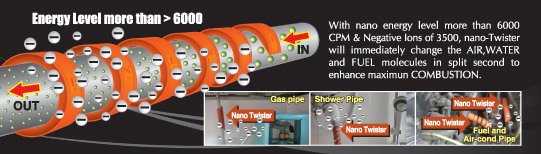

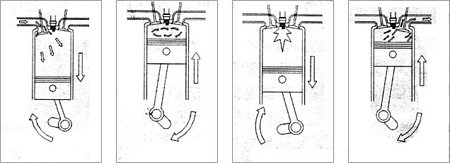

| The basic concept of the internal combustion engine Engine operation, the air entering the intake manifold and exhaust nozzle atomization of a mixture of gasoline mixed oil and gas, in the intake valves to the combustion chamber under the control, compressed issued by the spark plug sparks lit explosion, and then push the piston and generate power, burning a mixture of oil and gas after the exhaust valve and then sent by the exhaust pipe emissions into the atmosphere.

How to make the engine life expectancy: If gasoline almost complete combustion, the engine to reduce the number of carbon deposition on the relative and thus reduce the carbon content of oil, then oil will be pure, crankshaft piston and cylinder wall to reduce friction between, making the engine temperature is not caused by over-temperature metamorphism gasoline to extend the oil and engine life, relative to the increase in horsepower, engine running smoother and accelerate more smoothly and no longer need to spend to buy expensive high-priced oil, on weekdays only to maintain "intake valve throat" of cleaner and more may be growth engines for the use of life. Increased horsepower reasons: the original engine design - 150 |

| Nano technology today is growing very rapidly and has infinite applications in almost everything we do. The medicine we take, food we eat, chemicals we use, car we drive and much much more. Nano products in various forms as mentioned below. We offer many nano powders at very affordable prices. Material Formats:Atomic & Molecular Clusters, Buckyballs & Fullerenes, Bulk Nanostructured Metals, Magnetic Nanoparticles / Magnetic Nanostructures, Nanobelts, Nanolubricant Powders, Nanocrystals & Nanopowders, NanoFillers / NanoAdditives, Nanoparticles / Nanopowders, Nanoparticale Dispersions, Nanorods, Nanosponge Abrasives, Nano Tubes, Nanowires, Quantum Dots / Nano Dots, Reactive Electro Exploded Nano Powders. Carbon Nanotubes: Single wall (SWNT), Double wall (DWNT), Multiwall (MWNT), (alligned/tangled/dispersable), OH, COOH Functionalized SWNT/MWNT, Industrial Grade SWCNTs, MWCNTs, Conducting (Metallic) and Semiconducting SWCNTs, MWCNT Nonwoven Papers, CNT Foam, Special application CNTs. Other Nanotubes (Metals, Compounds, and Oxides/Hyroxides) Quantum Dots:Cadmium Mercury Telluride (CdHgTe), Cadmium Selenide (CdSe), Cadmium Selenide/Zinc Sulfide (CdSe/ZnS), Cadmium Sulfide (CdS), Cadmium Telluride (CdTe), Cadmium Telluride/Cadmium Sulfide (CdTe/CdS), Lead Selenide (PbSe), Lead Sulfide (PbS) Nano Dry Lubricant Powders: Tungsten Disulfide (WS2), Molybdenum Disulfide (MoS2), Hex-Boron Nitride (hBN), Graphite, Specially formulated Nano Lubricant Additive Powders to improve lubricity and save energy. Nano Powders: | ||||

|

| ||||

| ||||

|

| ||||

| Elements: Ag; Al; Au; B; C (diamond); C (Graphite); Co; Cr; Cu; Fe; Mn; Mo Ni; Sn; Si; Ti; TiH2; W; Zn Compounds: AlN; B4C; BN (hexagonal/cubic); B3N4 (hex.); CaS; CrB; Cr3C2; CrN; FeS; GaN (spher.); GaP; HgI2; InP; LaB6; Mo2B; Mo2C; MoS2; NbC; NbN; PbS; SiC; Si3(C0.5N0.5)4; Si3N4; TaC; TaN; TiB; TiC; TiC0.8N0.2; TiC0.7N0.3; TiC0.5N0.5; TiN; VC; VN; WB; WC; WC/Co; WN; ZnS; ZrB2; ZrC; ZrN Single Metal Oxides: Al2O3; Al(OH)3; B2O3; Bi2O3; CeO2; CoO; Co3O4; CrO3; Cr2O3; CuO; Dy2O3; Er2O3; Eu2O3; Fe2O3; Fe3O4; Gd2O3; HfO2; In2O3; In(OH)3; La2O3; MgO; Mg(OH)2; Mn2O3; Mn3O4; MoO3; Nd2O3; NiO; Ni2O3; PbO; Pr6O11; Sb2O3; SiO2; Sm2O3; SnO2; Tb4O7; TiO2 (anatase/rutile); VO; V2O3; V2O5; WO3; Y2O3; ZnO; ZrO2 Multielement Oxides: BaCO3; BaFe12O19; BaSO4; BaTiO3; CaCO3; Ca5(PO4)F; CoFe2O4; CuFe2O4; MgAl2O4; MgFe2O4; Li4Ti5O12; NiFe2O4; In2O3:SnO2; Li2CO3; LiCoO2; LiMn2O4; SrAl12O19; SrAl12O19; SrCO4; SrFe12O19; SrTiO3; Y3Al5O12 ZnFe2O4 Nanoparticle Dispersions: Nanoparticle dispersions are available in water, 2-Propanol, Toluene, Ethylene Glycol etc. Element Nanoparticle Dispersions: Carbon (Nanodiamond), Carbon (Carbon nanotubes), Cobalt, Copper, Gold, Iron, Platinum, Silicon, Silver, Titanium Oxide Nanoparticle Dispersions: Aluminum Oxide (Al2O3), Iron Oxide (Red, Yellow), Silicon Oxide (SiO2), Titanium Dioxide (TiO2) Anatase/Rutile, Zinc Oxide (ZnO) Rare Earth Oxide (REO) Nanoparticle Dispersions: CeO2, Dy2O3, Er2O3, Gd2O3, Ho2O3, Sm2O3, Y2O3, ZrO2 |